Designed to cater to a wide range of scientific and medical applications, our syringe pumps offer unparalleled accuracy in fluid injection and suction, handling volumes from nanoliters to milliliters, and pressures up to 15 bar. With intuitive interfaces and advanced programmability via PC, these devices ensure reliability and safety for consistent and precise experimentation. From managing multiple syringe channels simultaneously to accommodating various syringe sizes and customized flow rates, the Jikan syringe pumps are indispensable tools for researchers and laboratory technicians.

JIKAN ONLY MANUFACTURES RESEARCH SYRINGE PUMPS AND THEY SHOULD NOT BE USED FOR MEDICAL GOALS.

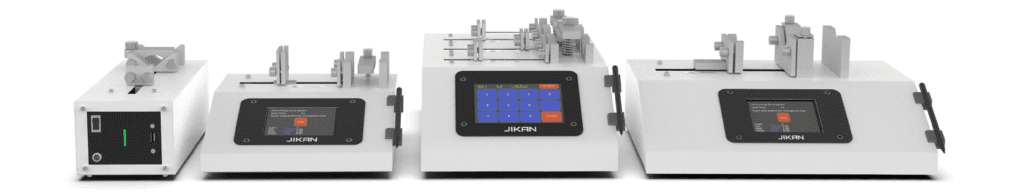

- Jikan SPM-Lite Specifications & Features

- Jikan SPM-10 Specifications & Features

- Jikan SPM-20 High-Pressure Syringe Pump Specifications & Features

- Jikan SPM-10 TC Syringe Pump Specifications and Features